Segmented disc valves

Robust, durable and highly precise in expanded line sizes

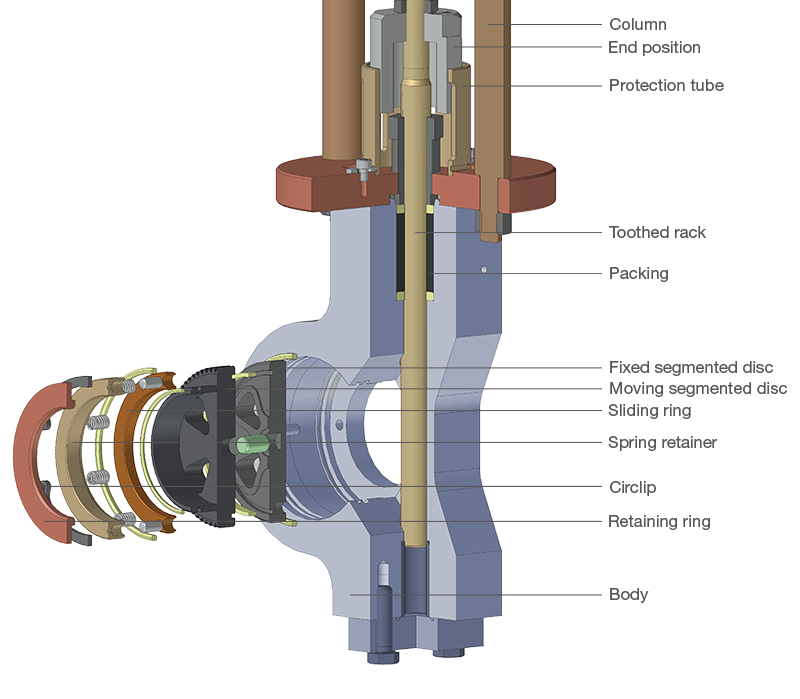

Functional principle of segmented disc valves

Segment disc valves incorporate a very simple yet effective design.

The central throttling element - a pair of segment discs that glide and seal against each other - are positioned in the valve body perpendicular to the flow direction. A fixed segment disc determines the Cv and flow characteristic. The fixed disc is engaged by a moving disc having the same geometry. Driven in a linear motion by a serrated actuator stem that sequentially increases or decreases the cross sectional area of the two segmented discs, these seating elements provide high rangeability with precise control.

The moving disc is spring loaded and this constant force allows bi-directional flow. The valve can also be installed in any direction and low differential pressures are nonproblematic.

This special design makes segment disc valves unique inasmuch as they combine precision control in extreme operating conditions with tight sealing and very low exposure to wear.