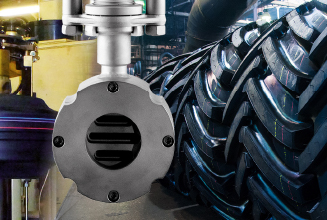

The production of tires can be particularly challenging for valves. Tire curing presses work at high steam, water and nitrogen pressures. Ambient conditions can be difficult with high temperatures and hydraulic inefficiencies. Succinct and precise process cycles require very robust valves with a high switching capability in these adverse conditions to achieve an acceptable life time and efficiency.

Two Schubert & Salzer valve types have proven themselves in this application with tens of thousands of installations all around the world for many years:

The angle seat valve 7010 in stainless steel features as on/off valve with high Cv values in a very compact design, with various connection options and very easy maintenance. The high temperature version, specifically developed for the service at curing presses, does ensure even high steam or hot water temperatures up to 428 °F, a long life time and shut-off reliability. They have also shown to be particularly durable against condensate and corrosive impacts from pipework or bladder deposits, providing the longest life time and best shut-off performance in the industry.

Control valve applications on the curing press are the shaping valve and the external platen & jacket valves, where the Schubert & Salzer sliding gate provides particular benefits due its unique features:

- long life, even in applications with high delta p and dynamic control operation,

- adaptability to different control requirements for various tire sizes, press and heating concepts by easily interchangeable Cv values/characteristics, Schubert & Salzer also develops tire production specific characteristics, which further increases the precision of control and the valve life time

- high control accuracy reduces the length of curing cycles, leading to improved productivity and less waste

- quick and easy maintenance by simple replacement of the valve discs

- the top mount integrated positioners make remote mounted i/p converters obsolete; pressure reducing valves which are common in conventional systems fronting the control valves are eliminated.

Additionally, sliding gate valves can be utilized in utilities as well as on main steam lines (steam headers), boilers, steam and N2 generation, mixers, calanders or chiller control.

Please find more information in our specific brochure for tire production.

Download brochure Schubert & Salzer - Your partner in Tire Production

Please more details also in our application report from world leading tire producer Continental.

Resins, plastics or rubber products are ever present in our daily lives. From automotive belts and hose, to polymer containers and bottles to medical and electronics industries… the list of products is almost endless.

The production process is complex and challenging requiring exact control of high temperatures and pressures to process raw materials into a diversity of final products.

Schubert & Salzer valves are further used in any production and processing application where molds are heated by steam or hot water, at thermal and smelting processes or where resins get mixed, cooled or are being processed in liquid form.

An application example can be the curing of cable molds, where sliding gate valves control steam and water for the thermal treatment of these rubber molds. They also control steam at presses for the production of CDs or LPs. Other applications can be found in the production of plastic pipes in cooling and calibration systems, at blow molding processes for fuel or chemical containers, barrels or at EPS- and PPS-foamed products.

A core process is the vulcanization of rubber products. Through high temperatures and pressures over a defined period a raw rubber-sulfur material gets stabilized against environmental, chemical and mechanical impacts. Only this this process turns raw products in to an elastic material for further processing.

This critical and complex production process puts high demands on the applied valves: compact sizes, high control valve rangeability, fast reaction, low energy consumption and simple maintenance.